Rosie will be on vacation until mid-February—guest blogger Melody Kettle will post in her place.

It’s like a spa for leafy greens. The sound of trickling water, a breath of warm humidity, and gently diffused natural light illuminating lush, purple and green foliage. If I were arugula, I’d be thrilled to be at Happy Harvest Hydroponic Farm in Denville.

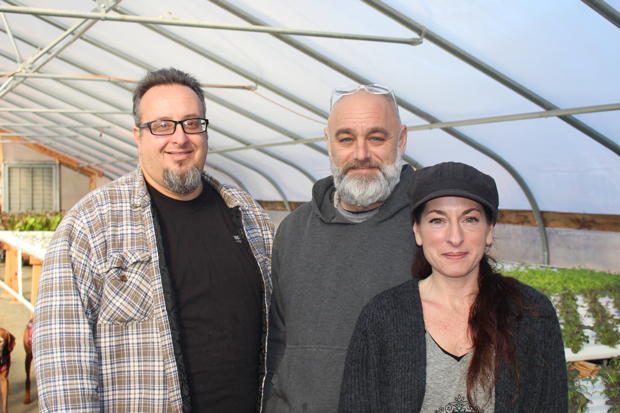

Rows of water-feed channels lush with Japanese Pepper Grass and Shanghai Spinach line the 3000-square-foot greenhouse. For co-owners, John Evangelista, Guy Botticelli and Cris Tuhy, Happy Harvest is a second career endeavor born of green thumbs and savvy economic evolution. Following the economic fallout of 2008, the landscape and construction businesses of Evangelista and Botticelli began to wane. Botticelli, who spent time working for an organically run private estate with vegetable and perennial gardens, and, of course, a greenhouse, suggested hydroponic growing as the next step in their collective careers.

Evangelista, Botticelli and Tuhy located a farm-assessed parcel of land to grow their idea, they still needed the greenhouse. They secured a previously owned structure, with the necessary cooling and heating machinery, located in upstate New York. For a week, Evangelista, Botticelli and Tuhy worked side-by-side to dismantle and resurrect the structure in Denville.

Now, eight months into operations, Happy Harvest is producing 300 pounds of produce weekly, and according to Evangelista they can “produce what a 3.5 acre soil farm can produce in a year using 80-90% less water.”

Under optimal conditions, the seed-to-plate process takes about 30 days, and begins with placing a seed in a porous cube of organic spun rockwool, called an Oasis pad. The Oasis pads are created to surround a seed with optimal moisture. For the first 10 days of propagation, a timed system releases a gentle stream of water for 5 to 10 minutes. The system then pauses for an hour to allow for proper absorption. Then, the cycle begins again.

After the propagation period, the young plant is transplanted to a channel. Larger plants that need more room will go to a “finished” channel, and other, more compact plants, go into a “nursery” channel. At this stage, constant watering begins. At all times, 550 gallons of water are circulated throughout the Happy Harvest system. On average, 30 to 50 gallons of water are consumed by the plants daily.

The science and success of hydroponic growing depends on the proper nutrient management of the water stream. Happy Harvest currently has three city water, tap-fed reservoirs: a 30-gallon propagation reservoir, an in-ground 850-gallon reservoir, and a third 100-gallon reservoir specifically nutrified for plants like basil that require a higher pH level.

Though all growing is done in-greenhouse, the cycle of production is still subject to the outdoor elements. The roof of the greenhouse is comprised of two layers of pliable plastic between which a controlled air system pumps temperature controlled air. According to Botticelli, “controlling the temperature of the greenhouse—air conditioning, but particularly heating—is the biggest expense."

Much of the Happy Harvest produce goes to the farmers market, like Denville or Sparta. And, all of the blends and product at the markets are from organic seeds.

The rest of the Happy Harvest produce is supplied to local New Jersey restaurants, like Escape in Montclair. Working with Happy Harvest, chef of owner of Escape, Bryan Gregg, is taking farm-to-table to a more focused level: seed to plate. This grown-on-demand relationship gives chefs like Gregg, the highest level of creativity and control over what they put on their plates. Beyond allowing chefs a quantified supply of hard-to-find greens like oxalis, types of sorrels, pursaline, and borage anytime of year, chefs could customize their leaves even further. For Gregg, Happy Harvest is currently refining a micro-green blend to single out particular leaves that he wants exclusively. The desired leaf will then be developed and grown to a maturity that exhibits the texture, tenderness and flavor profile Gregg wants. Looking forward, Happy Harvest will be developing micro vegetables for Gregg for use in pickling and cooking over yakatori.

Happy Harvest Hydroponic Farm, 68 Mt. Pleasant Turnpike, Denville. 973-931-3849.